| Quantity: | |

|---|---|

1、Features:

Under the same evaporation conditions, the larger the coating thicknessδ, the smaller square resistance (Ω/□) , the smaller the resistance R, the greater the load current, while the worse self healing properties.

Al metallized film has a better over-current performance.

Al metallized film has a better moisture resistance.

2、Types of Metallized Layer:

Margin size(mm):1.0±0.5、1.5±0.5、2.0±0.5、2.5±0.5、3.0±0.5、4.0±0.5、5.0±0.5

Coating square resistance(Ω/□):1.5±0.5、2.0±0.5、2.5±0.5、3.0±1

3、Cores:

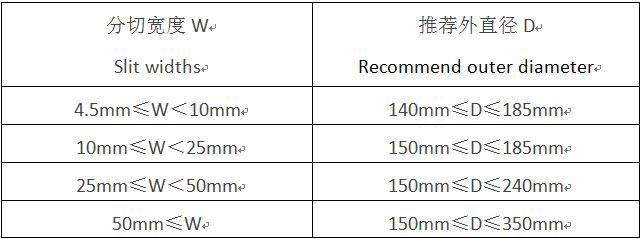

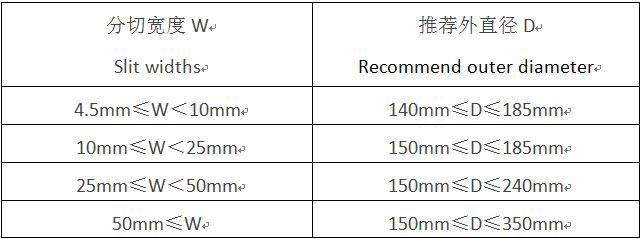

4、 Roll Outer Diameter:

| 性能 Properties | 单位 Unit | 要求 Requirements |

| 密度Density | g/cm3 | 0.905±0.005 |

| 厚度 Thickness | µm | 3.8 ~ 15 |

| 抗拉强度 Tensile Strength | 纵向MD (MPa) | ≥100 |

| 断裂伸长率 Elongation at Break | 纵向MD (%) | 40 ~ 200 |

| 热收缩率 Heat Shrinkage | 纵向MD (%) | ≤5 ( 120°C, 10min) ( 120°C , 10 min ) |

| 介电强度 Break-dowm voltage | V/µm | ≥350 ( 23°C, DC ) |

| 介电损耗因数 Dissipation Factor | - | ≤4×10-4 (20℃,1KHz ) |

| RC值 | ΩF | ≥5×104 |

6、Packing:

7、 Storge:

1、Metallized film should be stored in its original package until its use with temperature 5 ~35℃and humidity less than 85%RH.

2、Metallized layer is easily oxidized when exposure to moisture. Therefore, the film should be used as soon as possible when opened.

3、The recommended temperature is 15 -25℃with humidity less than 60%RH after the package is open.

4、With original sealed package, and stored in the above mentioned conditions, the storage time can be as following:

Al metalized Film: 12 months from the delivered date

Al/Zn Alloy metalized Film: As Zn is relatively unstable, preservation period depends on the resistance of the film:

Less than 10 Ohms: 6 months (from delivery date)

10 Ohms to 15 Ohms: 3 months (from delivery date)

15 Ohms: 1months (from delivery date)

1、Features:

Under the same evaporation conditions, the larger the coating thicknessδ, the smaller square resistance (Ω/□) , the smaller the resistance R, the greater the load current, while the worse self healing properties.

Al metallized film has a better over-current performance.

Al metallized film has a better moisture resistance.

2、Types of Metallized Layer:

Margin size(mm):1.0±0.5、1.5±0.5、2.0±0.5、2.5±0.5、3.0±0.5、4.0±0.5、5.0±0.5

Coating square resistance(Ω/□):1.5±0.5、2.0±0.5、2.5±0.5、3.0±1

3、Cores:

4、 Roll Outer Diameter:

| 性能 Properties | 单位 Unit | 要求 Requirements |

| 密度Density | g/cm3 | 0.905±0.005 |

| 厚度 Thickness | µm | 3.8 ~ 15 |

| 抗拉强度 Tensile Strength | 纵向MD (MPa) | ≥100 |

| 断裂伸长率 Elongation at Break | 纵向MD (%) | 40 ~ 200 |

| 热收缩率 Heat Shrinkage | 纵向MD (%) | ≤5 ( 120°C, 10min) ( 120°C , 10 min ) |

| 介电强度 Break-dowm voltage | V/µm | ≥350 ( 23°C, DC ) |

| 介电损耗因数 Dissipation Factor | - | ≤4×10-4 (20℃,1KHz ) |

| RC值 | ΩF | ≥5×104 |

6、Packing:

7、 Storge:

1、Metallized film should be stored in its original package until its use with temperature 5 ~35℃and humidity less than 85%RH.

2、Metallized layer is easily oxidized when exposure to moisture. Therefore, the film should be used as soon as possible when opened.

3、The recommended temperature is 15 -25℃with humidity less than 60%RH after the package is open.

4、With original sealed package, and stored in the above mentioned conditions, the storage time can be as following:

Al metalized Film: 12 months from the delivered date

Al/Zn Alloy metalized Film: As Zn is relatively unstable, preservation period depends on the resistance of the film:

Less than 10 Ohms: 6 months (from delivery date)

10 Ohms to 15 Ohms: 3 months (from delivery date)

15 Ohms: 1months (from delivery date)